Aluminum alloy brake disc

- Information

The new type of aluminum alloy brake disc is an innovative product newly launched by our company in response to the global demand for new energy vehicles and under the trend of automotive lightweighting. It is made of new aluminum alloy materials independently developed by our company.

Advantages of aluminum alloy brake discs:

1. Lighter weight:

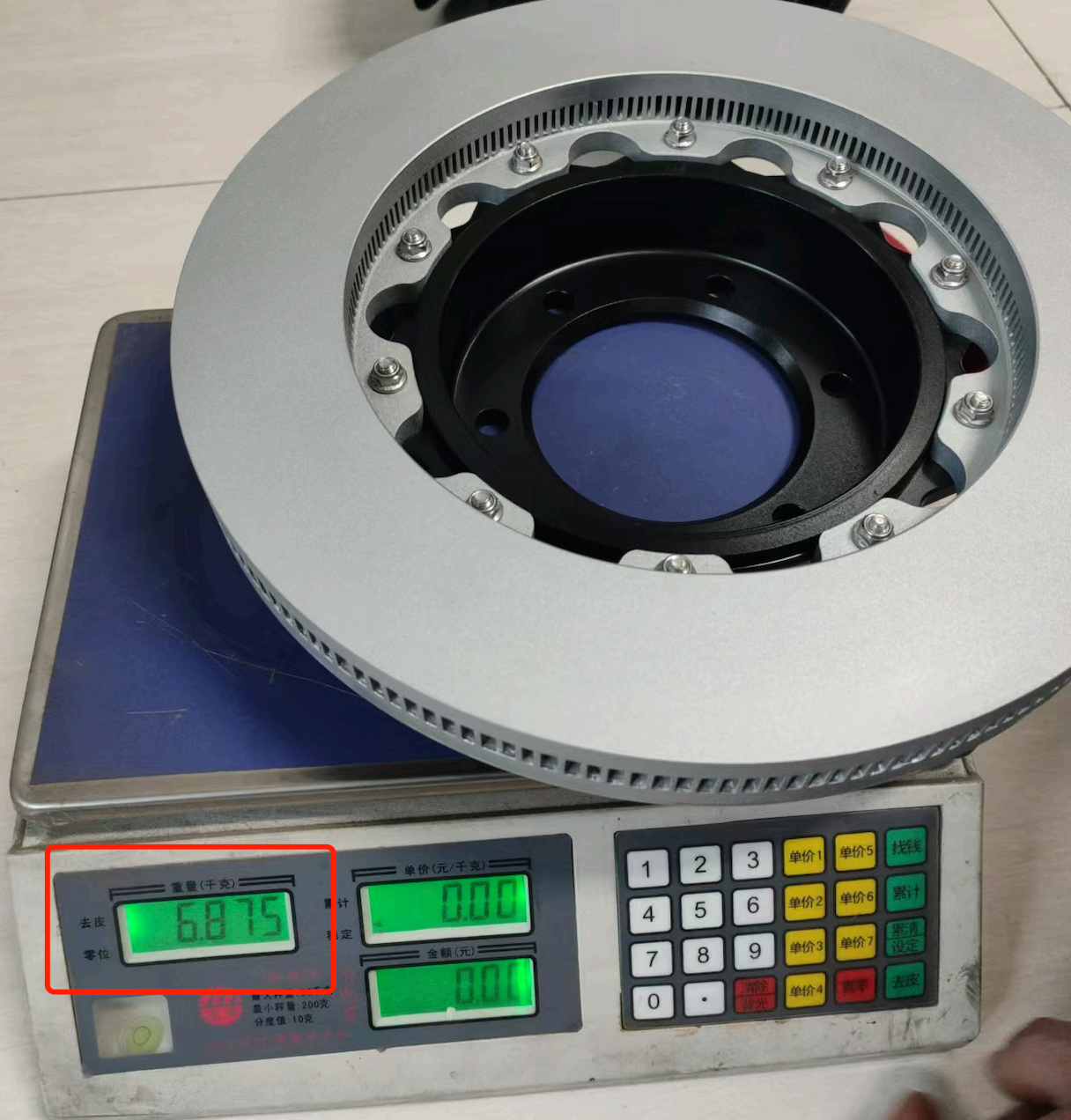

Aluminum alloy materials are approximately 40% lighter than iron brake discs, which can effectively increase the range of electric vehicles and reduce fuel consumption of cars. If the ventilation holes, grooves, and holes of the brake discs are further designed, the brake discs can be made even lighter.

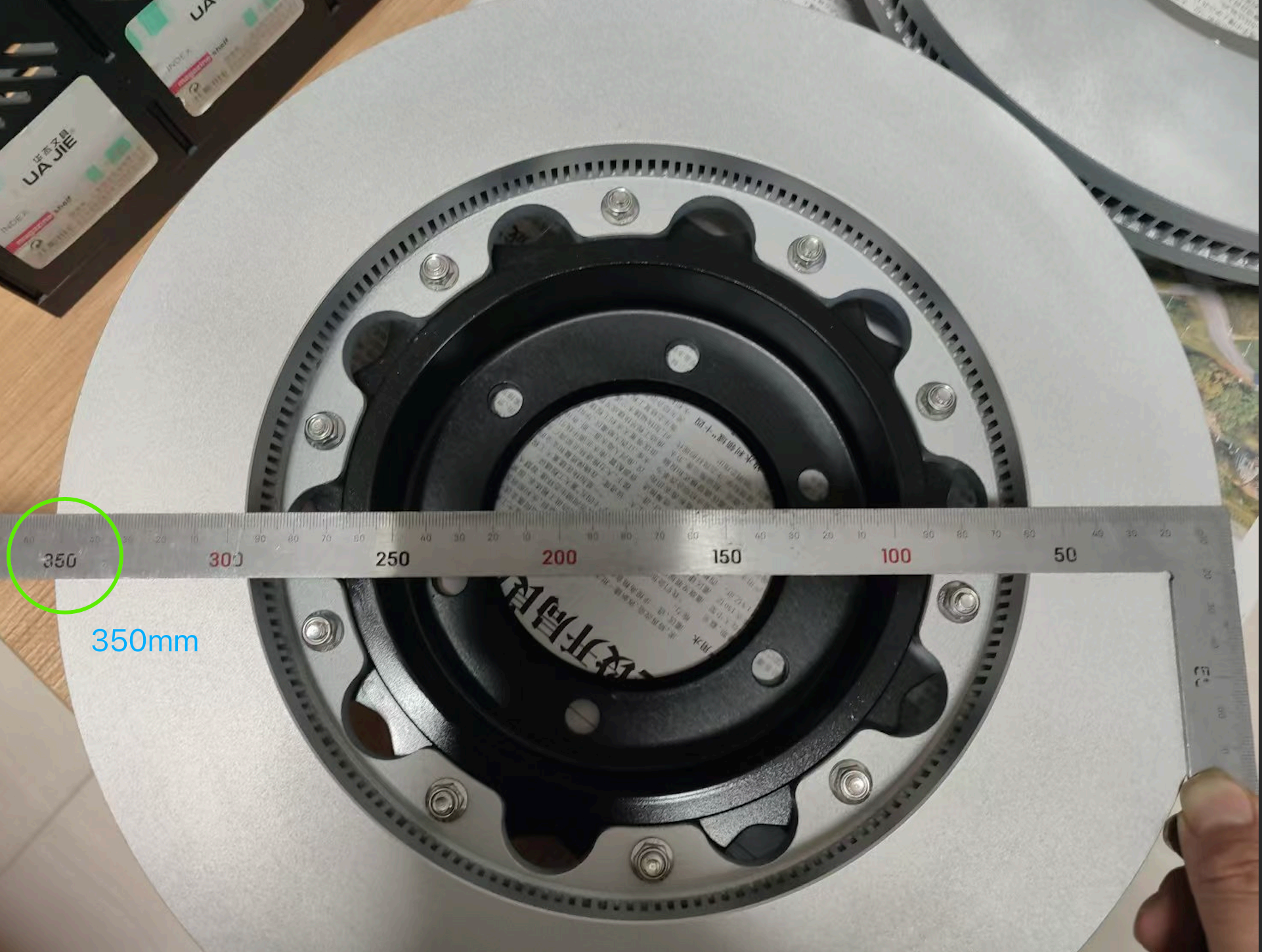

The outer diameter is 350mm, the inner diameter is 230mm, the thickness is 40mm, and the weight of the brake disc is only 6.87kg (including the joint and screws).

2. High temperature resistance and fast heat dissipation:

■ Aluminum alloy has a larger specific heat capacity. Compared with iron brake discs, aluminum alloy brake discs heat up more slowly under the same mass.

■ The thermal conductivity of aluminum alloy is three times that of iron. Under the same ventilation design conditions, the heat dissipation efficiency of aluminum alloy is higher.

■ It can withstand temperatures up to 600 degrees Celsius and still maintain braking performance and friction.

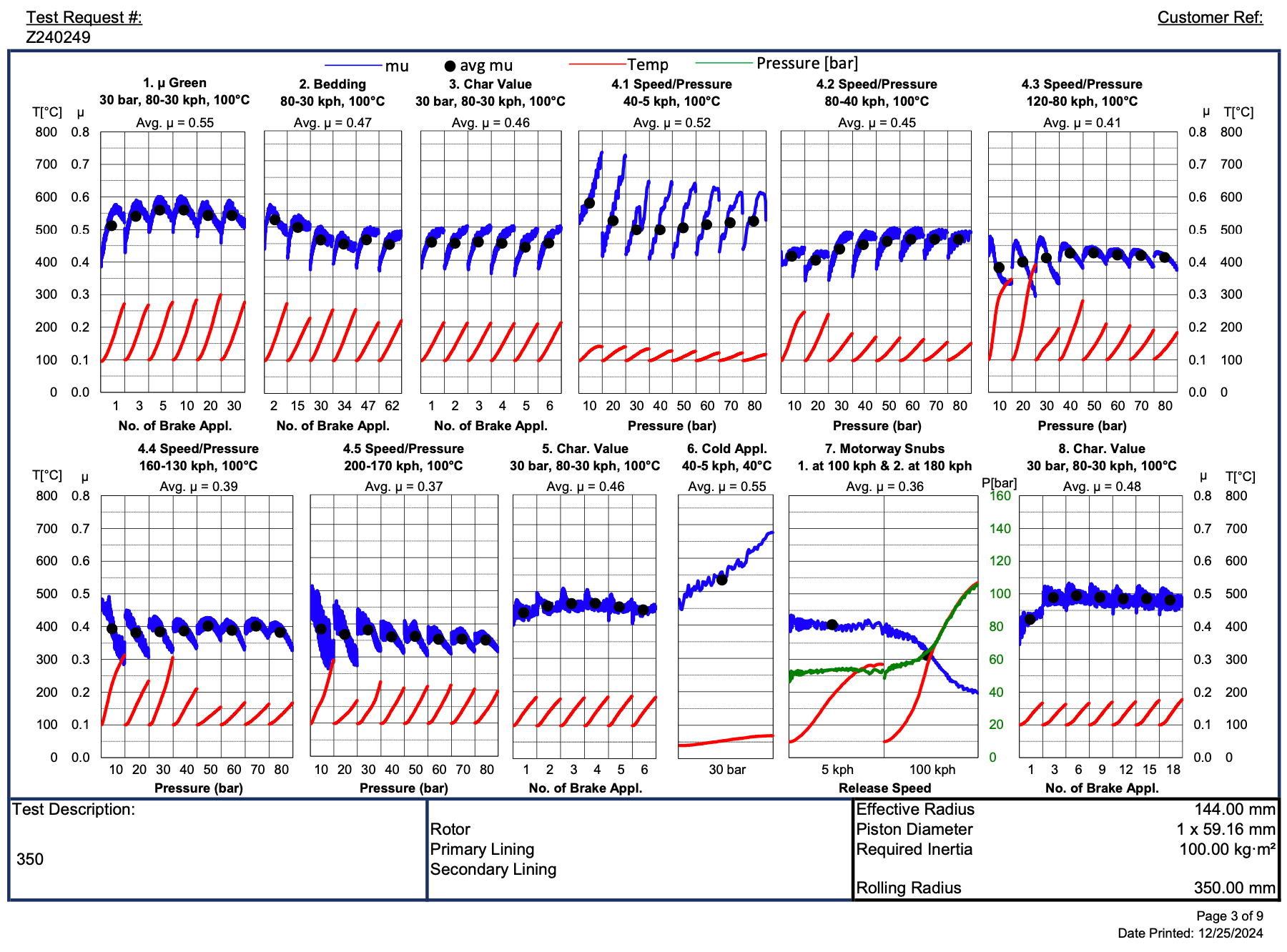

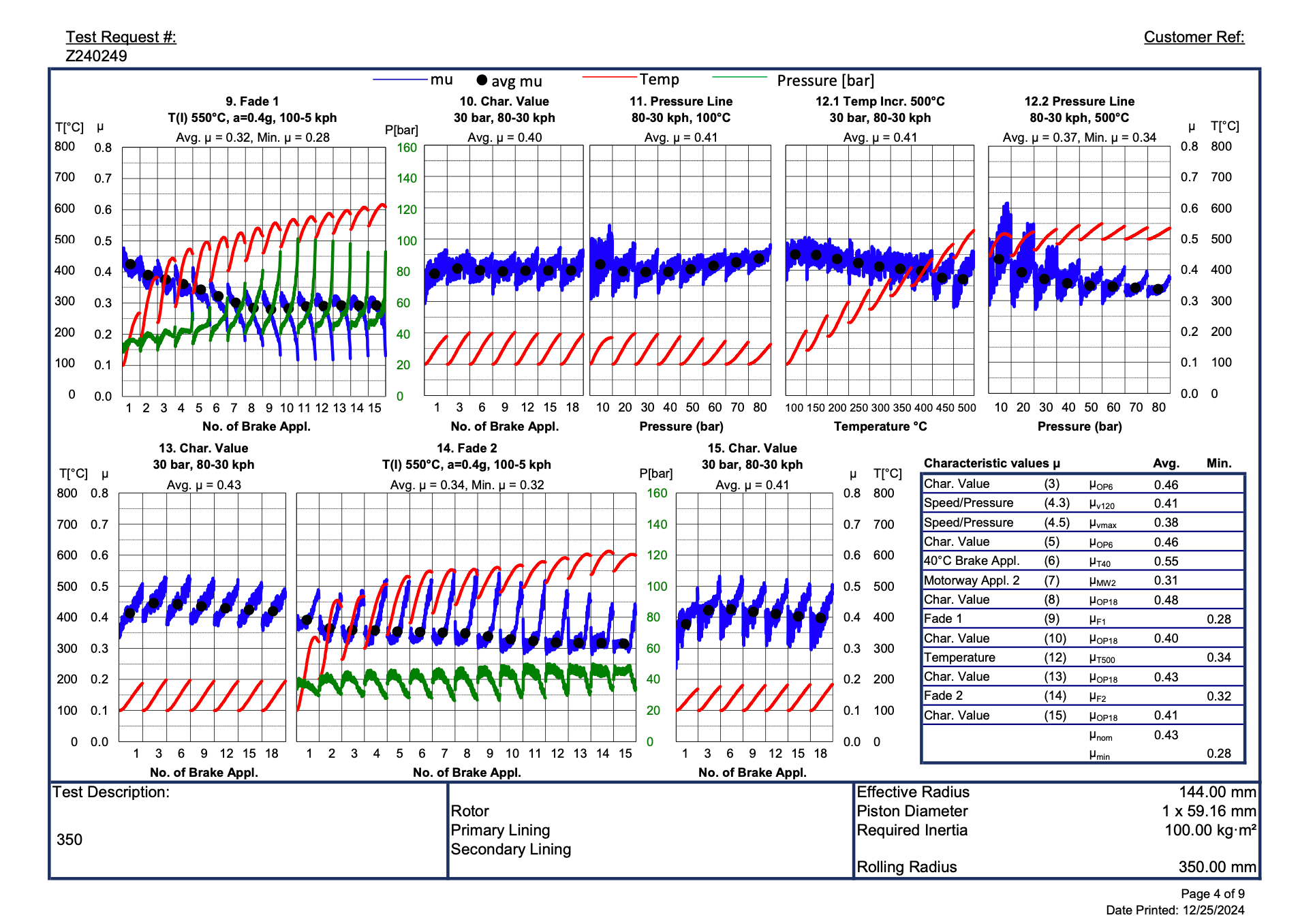

3. Stable friction coefficient with small fluctuations:

Under normal driving conditions, the friction coefficient of the brake is around 0.4 and is very stable.

4. High wear resistance and less dust:

The wear is very small and the dust is relatively less. Brake discs and brake pads need to be replaced only after about 200,000 kilometers of normal driving.

5. Very low noise, no sharp sounds, etc.

6. Brake pad size can be customized and developed, and the friction coefficient can be adjusted.

The following is the relevant situation of the brake disc friction coefficient test conducted on our product on the inertia bench of LINK.

This experiment was conducted in accordance with the standard of SAEJ2522.

As can be seen from the official report of LINK: In two intense thermal fade tests, the temperature reached a maximum of 600 degrees Celsius, and the coefficient of friction remained very stable.

After a complete SAEJ2522 test, the wear thickness of the brake discs was reduced by 0.003mm, and the thickness of the brake pads was reduced by 0.085mm.

Through experiments, it can be seen that the aluminum alloy brake discs produced by our company can still ensure braking effect and friction at a high temperature of 600 degrees Celsius. Coupled with the efficient heat dissipation efficiency, under long-distance braking conditions and frequent braking conditions, the friction coefficient can be more reliably maintained within the effective range.

Our company has the ability to adjust the design service life of brake discs through production processes and other means. At the same time, we can customize this type of brake discs according to your required dimensions and design graphics. We warmly welcome you to contact us and work together to create more energy-efficient and environmentally friendly automotive products.

Tianjin HuiNeng New Materials Technology Co., LTD

ADD: No. 1, Huajin Road, Niudaokou Branch, Tianbao Industrial Park, Baodi District, Tianjin, China

Tel: +86 022-29291825

Emai: hn@tj-huineng.com

Web: www.tj-huineng.com